- Type:

- Geocells, welded geocell

- Place of Origin:

- Hebei, China

- Brand Name:

- YUNDE

- Model Number:

- ASDMD

- Material:

- PP

- other name:

- Geoweb,Envirogrid,Strataweb

- Bonded Ranges:

- 330±2.5~800±2.5mm

- Cell Depth:

- 50,75,100,100,150,200,250mm

- Color:

- Black, Green or as per request

- Surface:

- smooth or textured

specifications

Good quality High strength HDPE Geocell factory

Geocell is a net-shaped cell structure made by welding high intensity thermoplastic

sheet. It is flexible: folded during transportation, stretching out and beingfilled with stone or concrete during service, and forming into struct with powerful

lateral confinement and rigidity.

Functions:

1.Fix railway ground.

2.Fix weak ground of roads.

3.Block loading capacity.

4.Treat river way of shallow water.

5.Act as support in pipeline and sewer.

6.Act as comprehensive block stopping land sliding and bearing loading capacity.

7.Act as independent wall, dock and break-water.

8.Treat desert, beach, riverbed and bank

Sheet Thickness, mm | 1.2±0.1/1.7±0.1 |

| ||

Bonded Ranges,mm | 330±2.5~800±2.5 |

| ||

Cell Depth,mm | 50,75,100,100,150,200,250 |

| ||

Properties | Test Method | Value |

| |

Material |

| HDPE |

| |

Standard color |

| Black/Green |

| |

Surface |

| Smooth/Textured |

| |

Sheet Thickness, mm | ASTM D5199 | 1.2±0.1/1.7±0.1 |

| |

Density, g/cm3 | ASTM D792 | >0.94 |

| |

Carbon Black Content,% | ASTM D1603 | >2.0 |

| |

Low Temperature Brittleness,C | ASTM D746 | <-77 |

| |

Environment Stress Crack Resistance,hours | ASTM D1693 | >4000 |

| |

Seam Peel Strength,N/100mm depth cell | COE GL-86-19 | 1000~1450 |

| |

Seam Hang Strength,days | HKCTM | Per 100mm seam shall sustain 72.5kg weight for at least 7 days,undergoing the variances from room temperature to 53°C on one hour cycle |

| |

Engineering Applications

1. A deal and a half to fill half roadbed

In Acts on a natural slope of the ground: the time when the construction of the embankment slope 5, embankments should be dug basement stairs, step width of not less than 1M, phased construction or alteration road widening, the convergence of the old and the new embankment fill slope should be open dig stairs, stairs highway width is generally 2M, at each step horizontal surface laying Geocell, Geocell own use facade unconfined reinforced effect, a better solution to the problem of uneven subsidence.

2, sand subgrade

Sand subgrade should be dominated by a low embankment, filling height is generally not to be less than 0.3M. Due to sand roadbed subgrade construction and professional requirements of low weight bearing, using Geocell can play loose filler unconfined role in limited the high level of protection embankment has a high stiffness and strength to withstand the load stress of large vehicles.

3, reinforced embankment abutment

Using Geocell can better achieve the purpose of abutment back stiffened, and filler between Geocell can generate enough friction, reduce uneven settlement between the roadbed and structures, and ultimately to effectively alleviate the "jump abutment car "diseases of early deck of impact damage.

4, Permafrost Regions

In permafrost regions fill embankment construction, should reach a minimum fill height, to prevent or cause a frozen layer Frothing ceiling fell, resulting in the occurrence of excessive embankment settlement. Geocell unique limiting overall facade reinforced side effects and effectively implemented, can ensure a minimum fill height in some special area of the maximum extent possible, and to fill a high-quality strength and stiffness.

The main purpose

1, for a solid road, railway embankment.

2, to withstand the load force and shallow river training dike.

3, is used to prevent landslides and by truck hybrid force retaining wall.

4, in the face of soft ground. Using Geocell construction can greatly reduce labor intensity, reducing the thickness of roadbed construction speed, good performance and greatly reduce the project cost.

packaging details

he products are usually packaged by packing tape; the packing size and the capacity of the containers is different from the specification of the products. We will package and transport the products according to the requirements of the buyers.

Reliability

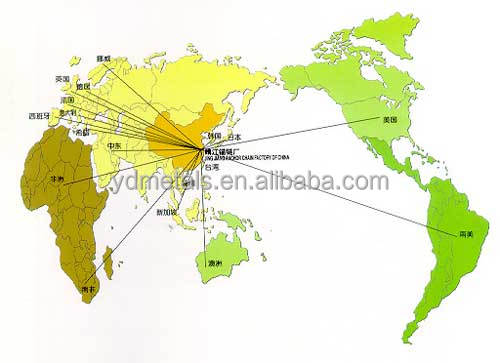

Founded in 1988, Yunde Metal has established itself as the premier option for expanded metal, perforated metal, bar grating and specialty metal products in China. Dedicated to unparalleled service, Yunde Metal has been more than 30 expanded metal,perforated metal and a number of external products, and our marketing at home and abroad, including Japan, Germany, Britain, Australia, the United States and other overseas countries.Welcome to visit the factory.

FAQ

1.About Yunde Metal

Founded in 1988, Yunde Metal has grown to become the premier fabricating distributor of metal products in China, located in Anping of Hebei Province-the famous Wire Mesh Land of China,Yunde offers superior customer service across all over the world serving customers from Europe to American.

2.THE lines YOU KNOW

Our comprehensive lines of products are the brands and standards you already know and trust.Yunde Steel, Stainless Steel and Aluminum bar gratings; Perforated Metals, Grip Strut, Perf-O Grip, Traction Tread Cable Trays, Safety Grating, Perforated Filter, Wind Dust Net and Perforated Corner Bead.

These quality products are those we feel are well-respected leaders in their field, providing our customers with continuing value, safety and durability.

3.PEOPLE MAKE THE DIFFERENCE

Yunde Metal while proudly serving the broad ranging needs of design professionals, the immediate requirements of general and sub-contractors, and the specific needs of end users. Our experienced staff will eagerly and competently assist in every facet of your application no-matter what kind of client or situation. We will gladly consult on the merits of our various products to help you select the most appropriate product for your application.