Product Description

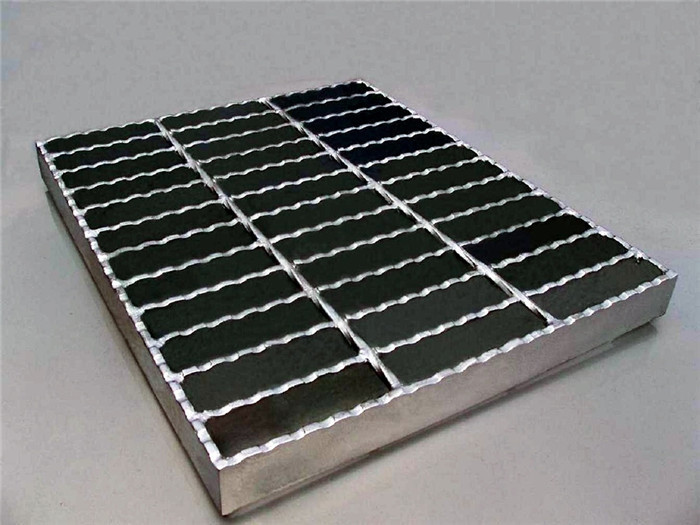

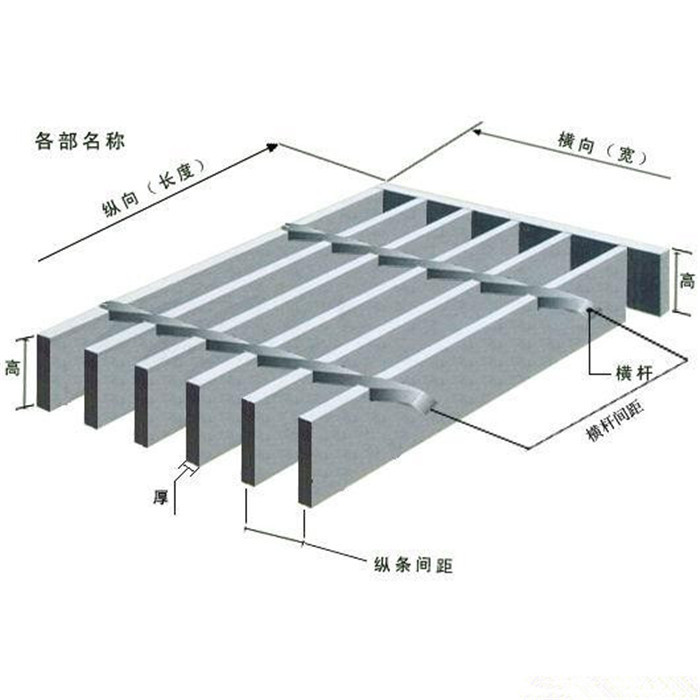

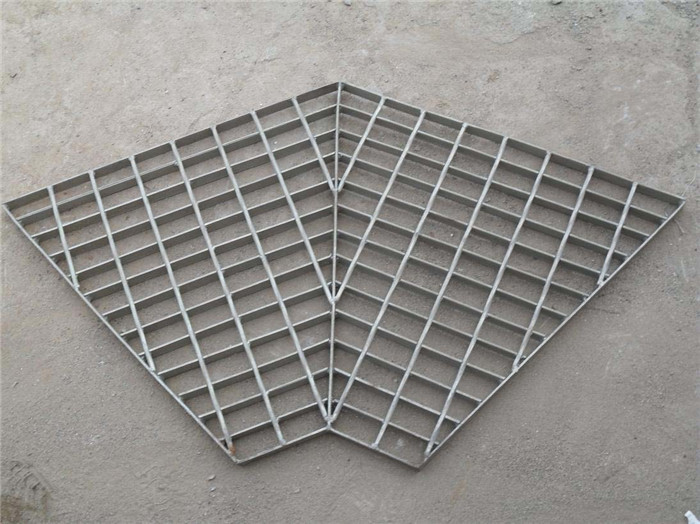

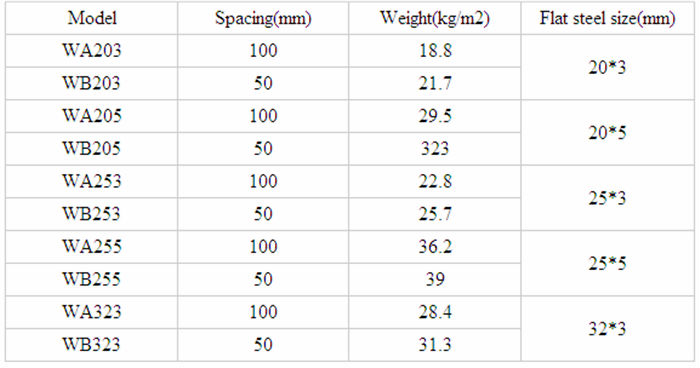

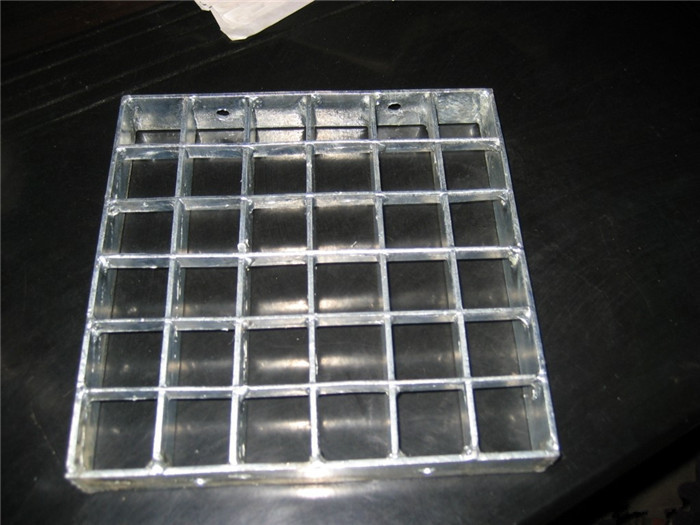

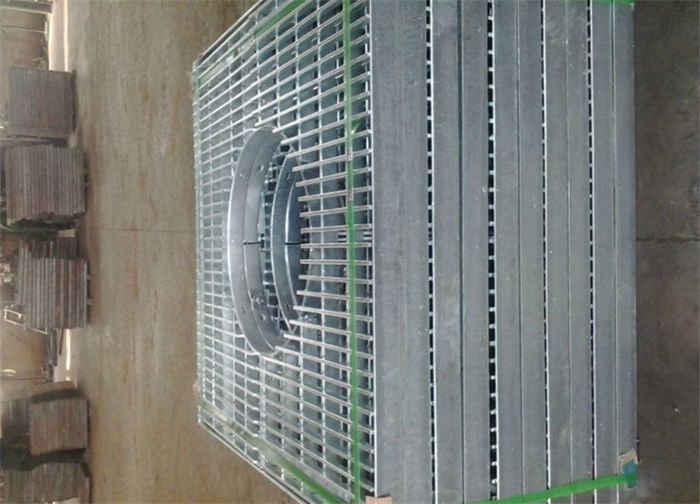

Galvanised Grating Material: high quality low carbon steel Types: serrated and plain Galvanised Grating Finishes: electro galv, hot dipped galv, according to the difference surface treatment. Types of steel grating: We produce three kinds of steel gratings, they are Plain Style Steel Grating, Serrated Style Steel Grating and I Bar Type Steel Grating. They are widely used in steel structure platforms, stair treads, sidewalks, drainages and well covers etc. Galvanised Grating Specification:

Galvanised Grating Material: high quality low carbon steel Types: serrated and plain Galvanised Grating Finishes: electro galv, hot dipped galv, according to the difference surface treatment. Types of steel grating: We produce three kinds of steel gratings, they are Plain Style Steel Grating, Serrated Style Steel Grating and I Bar Type Steel Grating. They are widely used in steel structure platforms, stair treads, sidewalks, drainages and well covers etc. Galvanised Grating Specification:

Galvanised Grating features (1)Attractive appearance:Simple outline.silver colour,and modern. (2)Optimum water draining:Water leakage area reaches 83.3%,which is more than two times larger than that of cast iron. (3)Hot-dip galvanizing:Good antirust performance,maintenance free and replacement free. (4)Design of preventing theft:The cover is connected with the frame by gemel,which ensures protection against theft,safety,and convenient opening. (5)Saving investment:With large span,the cost is lower than that of cast iron when under heavy load.And the replacement expenses in case of theft and crushing will be saved. (6)High strength:With strength:With strength and toughness far higher than those of cast iron,it can be used in the environment with large span and heavy load,such as the wharf and the airport. (7)Many specifications available: The requirement of different environments,loads,spans,sizes and shapes can be satisfied.

Galvanised Grating features (1)Attractive appearance:Simple outline.silver colour,and modern. (2)Optimum water draining:Water leakage area reaches 83.3%,which is more than two times larger than that of cast iron. (3)Hot-dip galvanizing:Good antirust performance,maintenance free and replacement free. (4)Design of preventing theft:The cover is connected with the frame by gemel,which ensures protection against theft,safety,and convenient opening. (5)Saving investment:With large span,the cost is lower than that of cast iron when under heavy load.And the replacement expenses in case of theft and crushing will be saved. (6)High strength:With strength:With strength and toughness far higher than those of cast iron,it can be used in the environment with large span and heavy load,such as the wharf and the airport. (7)Many specifications available: The requirement of different environments,loads,spans,sizes and shapes can be satisfied.

Installation of Galvanised Grating : 1.Welding & using saddle clips are two ways for installation of grating. The welding is suitable for those places where there is no need to move or dismental,for instance,the flooring around the machines. However,using saddle clips are featuring in easy installation & saving zinc layer. 2.Regarding welding installation, angle wolding would used at the first bearing bar of every corner,which the welding length is no less than 20mm,&the height is no less than 3mm. 3.Saddle clip composed of a top plate,a hold down & a M8 bolt, is suitable for all kinds of steel gratings installation. 4.Regarding saddle clip installation, at laest four sets of saddle clips would be used in one pc grating.It would be better using more in the staddle for those gratings with a bigger span. Usage of Galvanised Grating : widely used in petroleum chemical industry, power plants, water plants, sewage treatment plants, municipal works, sanitation engineering and other fields of the platforms, walkways, trench trestle bridge cover, covers, ladders, fence, fence, etc.

Installation of Galvanised Grating : 1.Welding & using saddle clips are two ways for installation of grating. The welding is suitable for those places where there is no need to move or dismental,for instance,the flooring around the machines. However,using saddle clips are featuring in easy installation & saving zinc layer. 2.Regarding welding installation, angle wolding would used at the first bearing bar of every corner,which the welding length is no less than 20mm,&the height is no less than 3mm. 3.Saddle clip composed of a top plate,a hold down & a M8 bolt, is suitable for all kinds of steel gratings installation. 4.Regarding saddle clip installation, at laest four sets of saddle clips would be used in one pc grating.It would be better using more in the staddle for those gratings with a bigger span. Usage of Galvanised Grating : widely used in petroleum chemical industry, power plants, water plants, sewage treatment plants, municipal works, sanitation engineering and other fields of the platforms, walkways, trench trestle bridge cover, covers, ladders, fence, fence, etc.

Packaging & Shipping